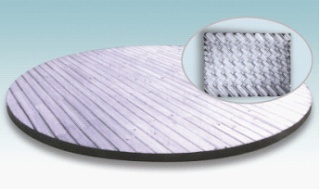

Column/Tower Internals

Column/Tower Internals Column Internals Distillation Technology and Plant Our company has excellent Column Internals technical personnel, including advanced and reliable means of processing, including laser technology. It can provide users with all kinds of services such as design, manufacture, guidance and installation of various tower parts according to different column diameters and different mass transfer needs, so as to meet users' different needs. The company can carry out the experiment of fluid mechanics to ensure the quality of the product. There are several kinds of inner parts produced by our company as follows: The liquid distributor and redistributor include the trough liquid distributor, the disc type liquid distributor, the tank tray type gas liquid distributor, and the pipe type liquid distributor. The trough type liquid distributor is a gravity type liquid distributor. It has excellent comprehensive properties: multi-function, low occupancy, anti fouling